Factory supply titanium alloy powder for industrial 3D printing

Product Features

1) Made by non-contact melting process.

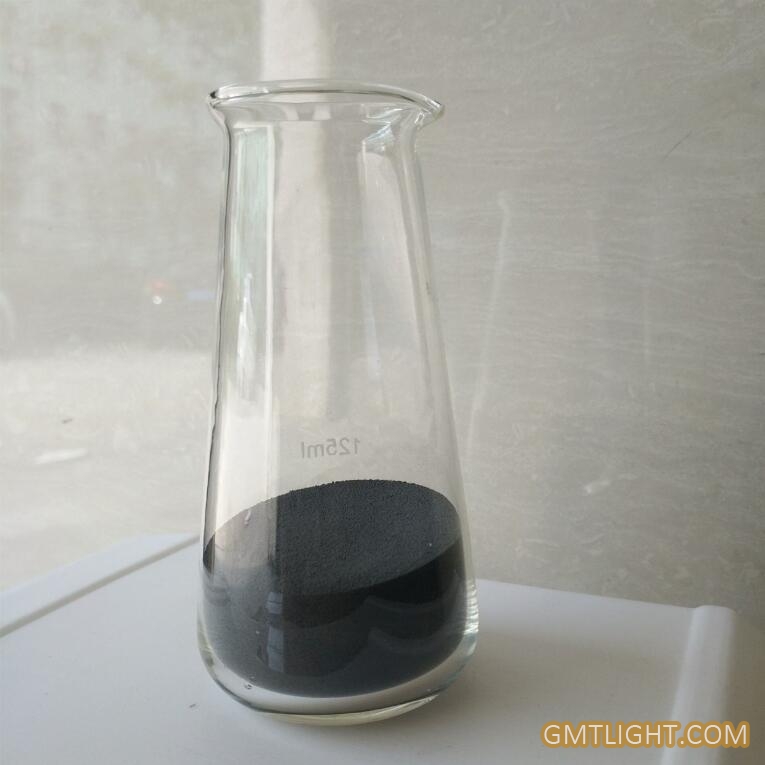

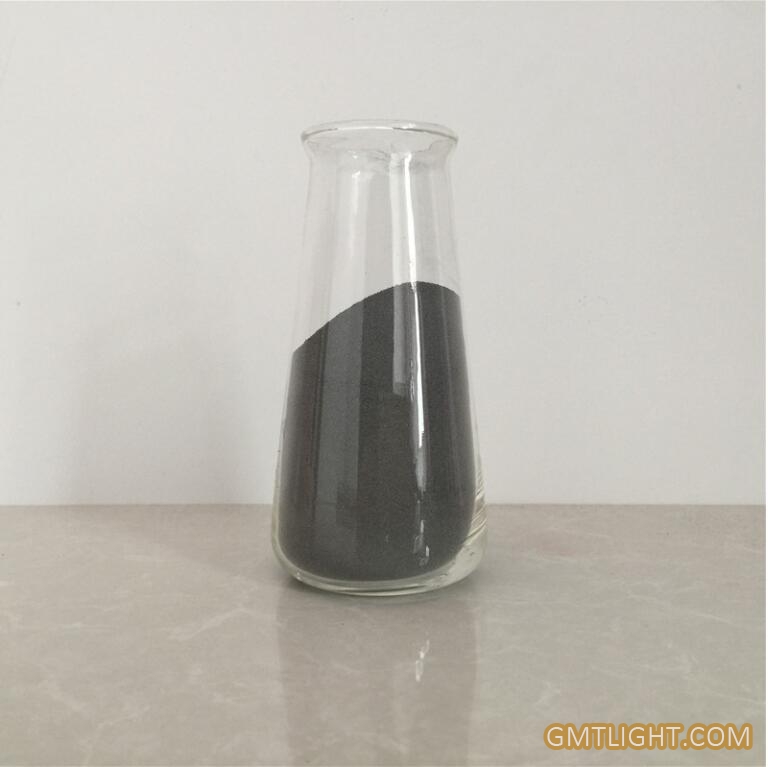

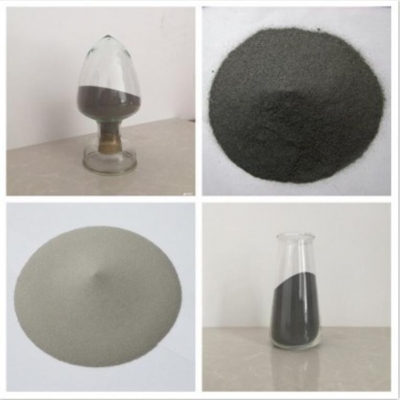

2) The powder has high sphericity, no hollow powder, narrow particle size distribution, good fluidity and strong density.

3) The particle size range of titanium alloy powder is 20-1000 μm.

4) Effective control of powder particle size distribution, sphericity and oxygen consumption through optimized technology.

5) Inert gas two steps treatment and compensation process can control the forming degree of titanium powder more efficiently.

Category | Alloy grades and characteristics |

Alloy | TA0,TA1,TC4,TC4 ELI,TC11,TC17,TC18,TC21, TA7,TA12,TA15,TA17,TA19,Ti40,Ti60, TiAl(Ti36Al,Ti48Al2Cr2Nb),TiNi,TiNb,ZrTi |

Powder granularity | 0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm |

Sphericity | Spherical or near spherical, microsphericity: Ψ0≥0.90 |

Appearance | Visual silver gray, no obvious oxidized particles. |

Preparation process | Vacuum Consumption+Forging/Casting Rod+Electrode Induction Purification Melting+Supersonic Gas Atomization Powder Production+Screening Classification+Inspection Packaging |

Packing | Vacuum packaging (Aluminum Foil Bag) |

| 3D printing application | SLM selective laser melting, EBM electron beam melting, LMD laser metal deposition, etc. |

| Other applications | Powder metallurgy (PM), injection molding (MIM), hot isostatic pressing (HIP), spraying (SP), welding repair, etc. |

Applications

Alloy powders have been applied in more and more extensive fields.

Technical features of the equipmentA) non-contact melting process, suitable for manufacturing active metals such as Ti, Al, U and its alloys.

B) the powder has high sphericity, no hollow powder, narrow particle size distribution, good fluidity and strong density.

C) the cooling rate of the powder can reach more than 105K/s

D) the particle size range of the powder is 20-1000 u m

E) effective control of powder particle size distribution, sphericity and oxygen consumption through optimized technology.

F) the equipment adopts the three stage cyclone grading collection system to improve the powder collection rate and reduce the fine dust emission.

A) the unique cyclonic double ring slot atomizer, in the production of droplets for two times atomization, improve the fine powder collection rate.

The production process

B) closed loop temperature control, the process temperature error is controlled at ±1℃.

C) inert gas two stage treatment and compensation process can control the forming degree of powder more efficiently.

D) reduce impurity content and keep environment clean through vacuum production process.

E) the equipment adopts multi-level dust removal system to ensure that the production process meets the environmental protection standard.

| Name | EIGA equipment for factory supply titanium powder producing |

Ultimate vacuum | 6.67×10-3Pa |

Pressure Rise Rate | <0.67Pa/h |

Vacuum Chamber | Double layer water cooling device, Stainless steel |

Electrode Material (EIGA) | Ti-V Alloy |

Electrode Size (EIGA) | DN30~DN100mm |

Max. Temperature (EIGA) | 1650℃ |

Heating Mode (EIGA) | High frequency induction heating |

Electrode Feed (EIGA) | 0-1000mm/min, Continuous Adjustment |

Electrode Feed Speed (EIGA) | 0-200RPM, Continuous Adjustment |

Control Mode | PID Programmable Control |

Safety Protection | Diaphragm proof device, Safety valve, Antistatic device, Mechanical proof device |

Circulating Water System | Cooling Water Flow Rate: 10T/H, Pressure: 0.25MPa Full closed control system Water inlet temperature ≤30℃, Water outlet temperature ≤45℃ |

Data Acquisition | Image acquisition of atomization process by computer |

Company Profile

As one of our technical partners, Hebei IMK Technology Co., Ltd. is a technology enterprise integrating 3D printing equipment development, material production, processing services and product sales. As a leader in application enhancement technology solutions, we focus on aerospace, automotive, medical, education, consumer goods industry solutions. The company has strong R & D capability and production capacity, and is in the leading industry level in many aspects such as equipment development, after sales service and so on.

We have established a complete industrial chain covering 3D printing equipment, 3D printing consumables, 3D printing processing services and 3D printing products promotion. 3D printing equipment is divided into three levels: education level, consumption level and industrial level, so as to meet the needs of different users. At present, more than ten invention patents and dozens of utility models have been mastered. With the scientific research team of Northeast Forestry University, using the agricultural and forestry waste as raw material, the new type of biomass laser 3D printing material is developed and produced. By virtue of the high quality printing effect and the economy, it is deeply recognized by the user. 3D printing and processing service is one of the main business. In addition to the self operated equipment, the company also has foreign imported industrial grade 3D printers. With the Internet manufacturing platform under its flag, the company can provide efficient and convenient manufacturing services for enterprises. We are moving forward on the road of innovation, and we hope that through technology, faith and our efforts, we will promote the transformation of the traditional manufacturing industry into the Internet + flexible manufacturing.

Hebei IMK Technology Co., Ltd.'s integrity, strength and product quality has been recognized by the industry. Welcome friends from all walks of life to visit, guide and negotiate business.