What are the processes for making customized samples? hand proofing?

Now hand proofing is more and more focused on speed and low cost, because only in this way, manufacturers who have demand for hand model will reduce the cost of product development and time risk, in order to get the first chance in the competitive market, then what are processing methods of hand proofing? With the development of technology, there are more and more hand printing methods. Here we introduce the commonly used hand-plate printing methods.

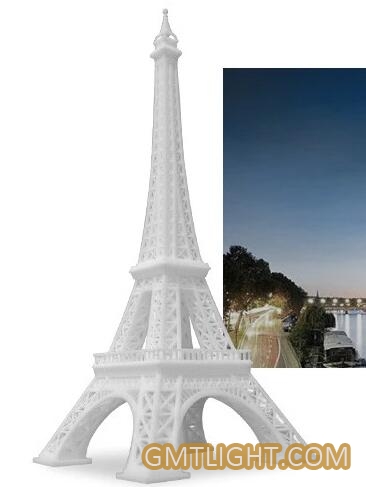

1. 3D printing board model

In fact, 3D printing is laser rapid prototyping, such as SLA/SLS, which belongs to 3D printing. The model of 3D printing hand plate is made by laser rapid prototyping machine as the first part, polished and removed as the model part of the mould. The advantage of 3D printing hand plate is to reduce the production cost and time cost. The technology has been mature and adopted by more and more manufacturers. The general structure and appearance hand plate can be printed with photosensitive resin, and the performance test hand plate can be printed with nylon. Many plastic samples of gmtlight are printed in 3D.

2. CNC Machine Tool Processing

CNC machine tools use computer control to ensure the accuracy of parts processed. CNC processing main materials are: ABS, PC, PMMA, PA, POM, PE, bakelite. ABS is the most common and commonly used plastic material. PC and PMMA are used to process transparent hand panels. PC is translucent and PMMA is translucent. CNC machining accuracy can reach (+0.05 mm). Processing equipment is also called CNC machine tools.

3. Making Handplate Model with Silica Gel Compound Mould

When gmtlight makes small batch hand boards, such as tens of hand boards, it is usually done by vacuum silica gel duplicating, because this kind of silica gel duplicating has short production cycle, low price and easy to occupy the market. Normally, the service life of silica gel mould is 15-20 times. Under vacuum conditions, the castables are defoamed, stirred, preheated and molded, and then cured in a constant temperature box. The strength and hardness of the hand plate model of silica gel compound mould can reach ABS and other materials

4. Low pressure perfusion

If high sample density is required, low pressure perfusion technique can be used. The material used is still epoxy resin, and the pressure used can reach 30-50 kg/cm2. Therefore, it is much better than the product of silica gel compound mold (vacuum compound mold). The physical properties of hand plate compound mold can reach 80% - 90% of the physical properties of injection products. It has the same characteristics as silica gel duplicate mold. It has low dimensional accuracy and is not a real plastic. It is suitable for 5-50 batches.

5. Rapid tooling

Simple die. It is to simplify the structure of the formal die and make the die exactly as the formal die. Then plastic machine injection processing, and then CNC processing, in order to meet the requirements of drawings. So the simple die is an organic combination of die technology and machining technology. Gmtlight is seldom used, and this cost is relatively high.

As a new hand plate processing technology, 3D printing has the characteristics of fast manufacturing time and low processing cost, and the processed products and traditional manufacturing methods are almost the same, so it is loved by more and more companies. Gmtlight has a complete set of 3-D printing workshop, which can print plastic, metal and other samples. A large number of models are completed by 3D printing.

友情提示:本网内容禁止转载,违者必究。