Development history of titanium alloy

Titanium alloy is a very important material, its development history has experienced more than half a century.

In the 1950s, an important metal structure developed, which is titanium. Titanium alloy is widely used in various fields because of its high strength, good corrosion resistance and high heat resistance. Many countries in the world have recognized the importance of titanium alloy materials, and have carried out research and development, and have been applied in practice.

In 1954, Ti-6Al-4V alloy was successfully developed in the United States. Because of its good heat resistance, strength, plasticity, toughness, formability, weldability, corrosion resistance and biocompatibility, Ti-6Al-4V alloy has become the leading alloy in the titanium alloy industry. The amount of Ti-6Al-4V alloy used accounts for 75% - 85% of all titanium alloys. Many other titanium alloys can be regarded as the modification of Ti-6Al-4V alloy. This is the first practical titanium alloy.

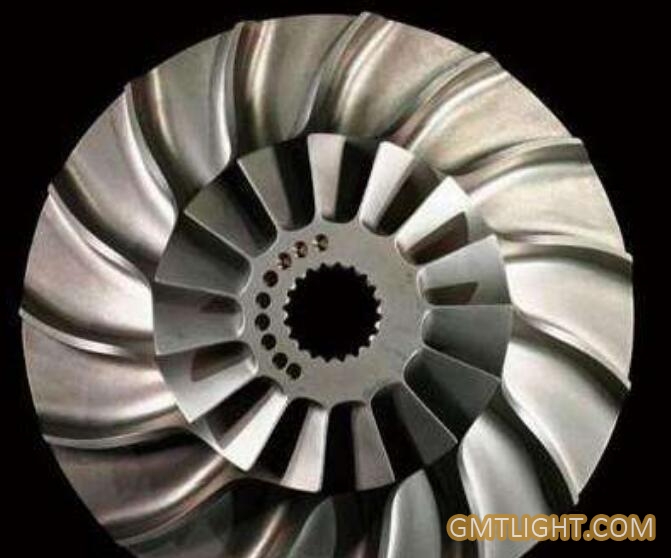

From 1950s to 1960s, high temperature titanium alloys for aeroengine and structural titanium alloys for airframe were mainly developed. In 1970s, a number of corrosion-resistant titanium alloys were developed. Since 1980s, corrosion-resistant titanium alloys and high-strength titanium alloys have been further developed. The service temperature of heat resistant titanium alloy has increased from 400 ℃ in 1950s to 600 ~ 650 ℃ in 1990s. With the appearance of A2 (Ti3Al) and R (TiAl) based alloys, titanium is being pushed from the cold end (fan and compressor) to the hot end (turbine) of the engine. Structural titanium alloys are developing towards high strength, high plasticity, high toughness, high modulus and high damage tolerance.

Memory titanium alloy has attracted worldwide attention.

Since the 1970s, shape memory alloys such as Ti Ni, Ti Ni Fe, Ti Ni NB have appeared, and have been widely used in engineering.

Hundreds of titanium alloys have been developed in the world, among which 20-30 are the most famous ones, such as Ti-6Al-4V, ti-5al-2.5sn, Ti-2Al-2.5Zr, ti-32mo, Ti Mo Ni, Ti PD, SP-700, ti-6242, ti-10-5-3, Ti-1023, BT9, BT20, imi829, imi834, etc.

In 2012, China's chemical industry consumed 25000 tons of titanium. The chemical industry has always been the largest user of titanium processing materials, and the proportion of its consumption in the total consumption of titanium materials has been maintained at more than 50%, accounting for 55% in 2011. However, with the economic downturn, the chemical industry will not only significantly reduce the number of new projects, but also face the situation of industrial structure adjustment, the new production capacity of some products will be controlled, and the backward production capacity will be gradually eliminated. Affected by this, the amount of titanium processing materials is also shrinking.

Nowadays, there are many civil products such as titanium alloy bicycle, titanium alloy helmet and medical titanium alloy. The prospect of titanium alloy in civil market is still broad, and its application is extremely wide.

3D printing department,gmtlight。