What is carbon fiber? Who was the earliest inventor of carbon fiber?

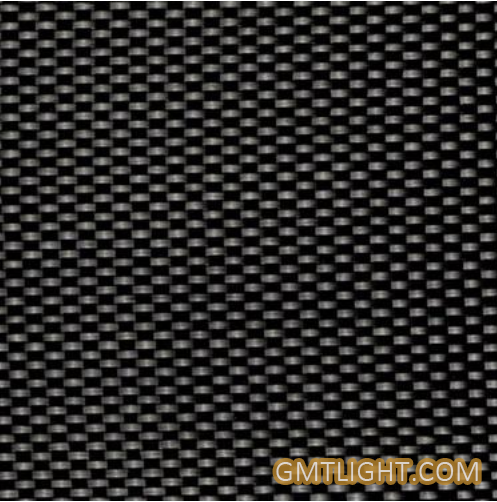

Carbon fiber is a kind of high strength and high modulus fiber with more than 90% carbon content. The high temperature strength of carbon fiber ranks first among all chemical fibers. Carbon fiber is made of acrylic fiber and viscose fiber through high temperature oxidation and carbonization. It is an excellent material for manufacturing aerospace and other high-tech equipment.

General summary: carbon fiber is a kind of special fiber composed of carbon elements. Carbon fiber has the characteristics of high temperature resistance, friction resistance, electrical conductivity, thermal conductivity and corrosion resistance. The shape of carbon fiber is fibrous, soft and can be processed into various fabrics. Due to the preferred orientation of graphite microcrystalline structure along the fiber axis, it has high strength and modulus along the fiber axis.

The density of carbon fiber is low, so its specific strength and specific modulus are high. The main purpose of carbon fiber is to composite with resin, metal, ceramic and carbon as reinforcing material to make advanced composite materials. The specific strength and specific modulus of carbon fiber reinforced epoxy resin composites are the highest among the existing engineering materials.

Who was the earliest inventor of carbon fiber?

In 1879, Edison used cellulose fiber, such as bamboo, flax or cotton yarn as raw materials to produce carbon fiber, which was patented. However, the mechanical properties of the fiber were very low, and the process could not be industrialized.

In the early 1950s, due to the development of rocket, aerospace and aviation technology, new materials with high strength, high modulus and high temperature resistance are urgently needed. In addition, carbon fiber continuous filament can be prepared by using precursor fiber as raw material through heat treatment process, which lays the foundation for carbon fiber industrialization. Over the past 40 years, carbon fiber has experienced the following major technological advances:

In the early 1950s, Wright Patterson Air Force base of the United States successfully trial produced carbon fiber with viscose fiber as raw material. The product was used as ablative material for rocket nozzle and nose cone with good effect.

In the early 1960s, Japan's Kato shoo invented the method of making carbon fiber from polyacrylonitrile (Pan) fiber and obtained a patent.

In 1965, suguro Otani first made PVC pitch based carbon fiber, and published a pioneering research report on pitch based carbon fiber.

In 1969, Japanese carbon company successfully developed high performance polyacrylonitrile based carbon fiber. In 1970, Toray textile Inc. of Japan developed high-performance polyacrylonitrile based carbon fiber by relying on advanced polyacrylonitrile precursor technology and exchanging carbonization technology with United carbide company of America.

Torayca was put on the market in 1971.

In 1970, Japan's Wuyu chemical industry company adopted the patent of suguro Otani, and first built a production plant with an annual output of 120t common type (gpcf) pitch based carbon fiber. In 1978, the output increased to 240t. After being used as cement reinforcing material, the effect is very good.

Since 1982, Toray, Toho, Japan carbon company, Hercules, Celanese company and Courtaulds company have successively produced high strength, ultra high strength, high modulus, ultra high modulus, high strength medium modulus and high strength high modulus high performance products. The tensile strength of carbon fiber has increased from 3.5gpa to 5.5gpa, and that of small-scale products has reached 7.0gpa. The modulus of carbon fiber is increased from 230 GPa to 600 GPA, which is a great breakthrough in carbon fiber technology and brings the application and development to a new high level.

Since 1981, great progress has been made in pitch science, and several new processes for preparing mesophase pitch have been developed, such as the pre mesophase process of Kyushu Industrial Test Institute in Japan, the new mesophase process of Exxon company in the United States, and the potential mesophase process developed by qunma University in Japan, which have promoted the development of high performance pitch based carbon fibers.

At present, the main products of carbon fiber are polyacrylonitrile based, pitch based and viscose based, and each type of product is divided into many varieties due to different types of raw fiber, process and final performance of carbon fiber“ The term "carbon fiber" is actually the general term of many kinds of carbon fibers.

In the early 1990s, high-performance and ultra-high-performance carbon fibers have come out. Since then, the technology has been improved, production expanded, cost reduced and application developed.

Nowadays, the field of carbon fiber is a big family, and many composites also have carbon fiber.

The above content is provided by gmtlight technology department.